KMAS/Hydroforming Introduction:

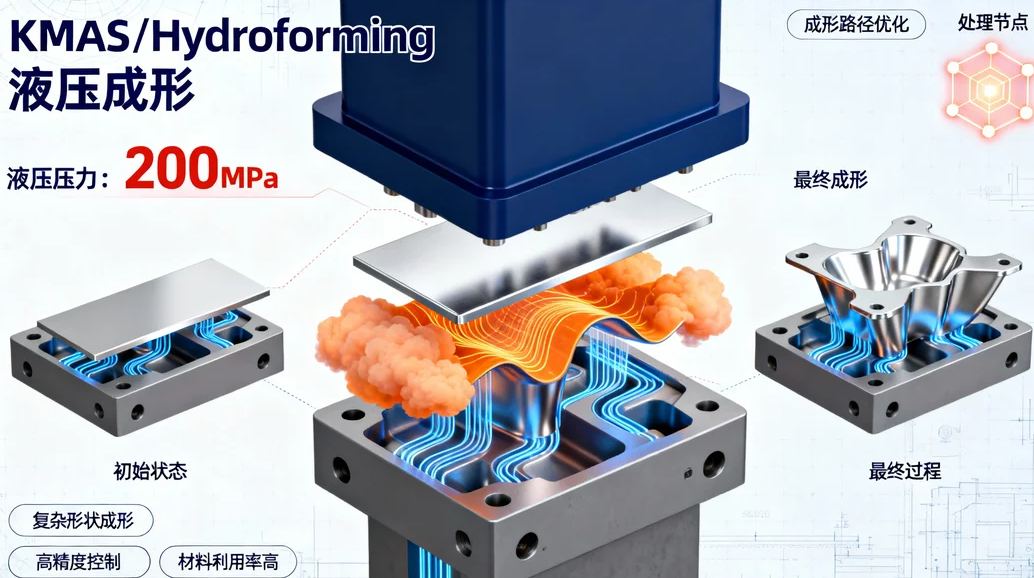

KMAS/Hydroforming (hydroforming) is currently primarily used for forming tubular components in the automotive industry. The hydroforming process is illustrated in Figure 1: First, the tubular blank is filled with a water-soluble emulsion (approximately 5% concentration), and then the mold is closed. Under the combined action of internal pressure and two opposing axial forces along the initial axis of the tubular blank, the blank fills the mold cavity. The main function of the KMAS hydroforming module is to determine the appropriate loading path (axial feed speed and internal pressure curve over time) based on given material parameters of the blank, part geometry, and the friction coefficient at the mold-blank interface. This ensures the avoidance of defects such as buckling, wrinkling, and cracking, resulting in qualified products.

KMAS/Hydroforming enables you to:

· Achieve rapid mold and process design for hydroforming parts;

· Reduce mold manufacturing costs and shorten development cycles;

· Improve part quality;

· Enhance process reliability.

Key Features of KMAS/Hydroforming:

· Utilizes quadrilateral shell elements;

· Employs a static-explicit algorithm to compute the quasi-static tube forming process, delivering higher precision.