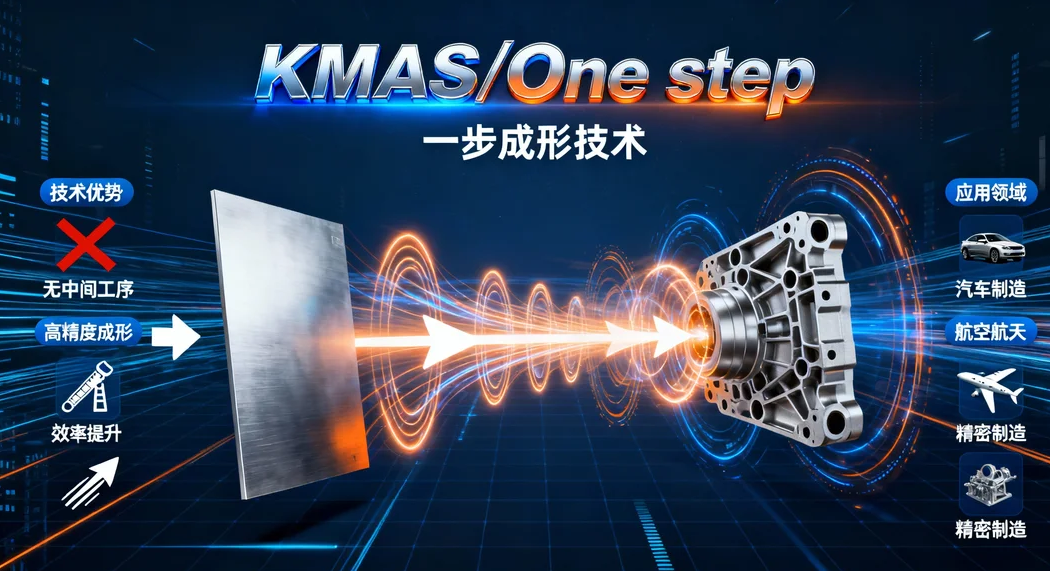

KMAS/One Step (One-Step Molding) Function Introduction: One Step employs a product-based one-step molding algorithm (Onestep Codes) aimed at iteratively optimizing and simulating the product multiple times. First, input the part's mesh data, set some process parameters, and quickly obtain the minimum blank shape, forming defects such as cracks and wrinkles, FLD (Flexible Floor Deformation), and forming results reflecting quality objectives such as elongation and thickness variation. It discusses product manufacturability, can perform blank back-calculation, and quickly evaluate the manufacturability of parts. KMAS/One Step allows you to: • Analyze typical mesh data in just a few minutes. • Predicted blank shape can be used for early cost analysis, part layout, and design optimization to reduce trial runs. The optimal blank shape can also be expanded to output in Nastran format for other applications. • In post-processing, it provides engineers with results such as wrinkles, cracks, forming defects, FLD, and thickness distribution for iterative product optimization and multiple simulations. • Quickly predict the part forming process, facilitating more rational design. • Introducing the analysis results into collision analysis can yield more accurate collision analysis results.

• This allows designers to assess the manufacturability of parts early in the design process, improving design effectiveness and reducing the number of mold design changes. KMAS/One-step Features: Fast and precise solution. Short solution time. Blank shape estimation, providing thickness, stress, and strain distribution on the final part. Applying appropriate boundary conditions: such as blank holder force and stretch ribs. Quickly (typically sized parts within minutes) completes part forming prediction and obtains the unfolded blank. Simple and engineering-oriented Top/View operation. Provides automatic nesting functionality. Based on the UGS NX system. The core module KMAS/one-step has been integrated into the SIEMENS|NX_PLM software system and was officially launched to the mainstream international automotive and mold manufacturing markets in the fourth quarter of 2006. One-step uses a product-only one-step forming algorithm (Onestep Codes), aiming to perform multiple simulations for iterative optimization of the product. First, input the mesh data of the part and set some process parameters. This quickly yields the minimum forming defects such as burrs, cracks, and wrinkles, as well as the forming result (FLD) reflecting quality targets such as elongation and thickness variation. It discusses product manufacturability, enables reverse calculation of blanks, and provides a rapid evaluation of part manufacturability.

Product Detail

Product Parameter